![M27 with magazines and SDO removed. Notice the interconnecting monolithic 12 o’clock rail. Display of various magazines. From left; standard issue 30 round STANAG magazine with green follower, similar magazine design but has orange follower to show it has an anti-tilt follower, H&K steel 30 round magazine, works very well with M27(not issued), popular PMAG will not fit in M27.]()

M27 with magazines and SDO removed. Notice the interconnecting monolithic 12 o’clock rail. Display of various magazines. From left; standard issue 30 round STANAG magazine with green follower, similar magazine design but has orange follower to show it has an anti-tilt follower, H&K steel 30 round magazine, works very well with M27(not issued), popular PMAG will not fit in M27.

(This Article first appeared in Small Arms Review in 2012)

Miles Vining

This is the first part of a two-part article on the new M27 automatic rifle, now in service with the United States Marine Corps. The first part will cover initial use and training while the second will cover performance in combat. The author is a Marine infantryman serving with 1st Battalion, 9th Marines, deploying to Afghanistan in 2011.

Note: All dimensions, acronyms and official terms are from Marine Corps terminology and references.

Background

Finding the perfect balance between firepower, weight, reliability and ammunition capacity has constantly been a challenge for Light Machine Gun (LMG) development. These support weapons for the traditional infantry squad have usually been a compromise among these four factors. The BAR lacked the magazine capacity to be truly successful, while the M60 gained the infamous nickname of the “Pig” due to its excessive weight and bulk. The M249 Squad Automatic Weapon (SAW) came very close to being the exemplary LMG but quickly lost its glory through its high malfunction rate and weight. Recently, the United States Marine Corps has decided upon a solution that takes the Squad Automatic Weapon to whole new level.

![Displayed are three of the Marine Infantry squads current issue weaponry; M16A4 for riflemen, M27 for IAR gunners, and M4s with M203s for team and squad leaders. The M27 and M16A4 displayed have 3 point slings while the M4 has a 1 point. M4 and M27 have their stocks fully extended. Positioning of the laser emitting PEQ16 is up to the individual Marines discretion.]()

Displayed are three of the Marine Infantry squads current issue weaponry; M16A4 for riflemen, M27 for IAR gunners, and M4s with M203s for team and squad leaders. The M27 and M16A4 displayed have 3 point slings while the M4 has a 1 point. M4 and M27 have their stocks fully extended. Positioning of the laser emitting PEQ16 is up to the individual Marines discretion.

Several years ago, while observing a Marine unit conducting pre-deployment training on Range 410 Alpha in Enhanced Mojave Viper, Twentynine Palms, California, a high-ranking officer watched a squad clear a trench as part of the training exercise. The squad’s SAW gunners established a support by fire position while the squad rushed into the trench and continued on with the range. After it was over, the officer asked the battalion Gunner (Chief Warrant Officer, an expert on Infantry small arms and tactics) why the SAWs couldn’t come into the trench with the main effort. The answer given was that the SAWs would slow the squad down and could not be effective in the trench because of the guns weight and open bolt operation. Finding this tactic detrimental to the way Marines fight today, the officer and battalion gunner decided to act. Requests were made to the firearms manufacturing community and a competition for a new squad LMG ensued.

The competition was designated the “Infantry Automatic Rifle” and the Marine Corps made it very clear that it had to fill the place of the SAW but also be a lighter and more portable weapon. Changing the designation from SAW to IAR showed that the Marine Corps was dedicated in finding a mobile automatic platform instead of being burdened down with the old technology. It had to weigh less than 12.5 pounds and accept 30 round STANAG magazines. It had to fulfill the function of the SAW but also be lighter and more mobile. Six commercial companies accepted the challenge, and three made it down to final testing: FN Herstal, Heckler & Koch (H&K), and Colt. FN’s contender was a modified SCAR, H&K’s and Colt’s weapons were both modified versions of their respective entries into the Black Rifle market. All except H&Ks were open bolt. After months of exhaustive testing, H&K came out on top. Trumping its competitors in areas of accuracy, reliability and malfunctions, the H&K submission produced outstanding results. Most of the malfunctions were classified as “user error” and accuracy was unparalleled compared to the other two. In fact, it is reputed to be the second most accurate weapon in the Marine Corps inventory after the M40A3 sniper rifle. Designated as the M27, H&K had proven itself once again.

![Trijicon SDO gear pouch with accessories. The gear bag is manufactured by Eagle Industries and is issued with every M27. Marine Corps T M 11758A-OR for the SDO/RMR and TM11810A-OR for the M27 are displayed top and bottom respectfully. M27 wrench is shown disassembled to left of SDO Lens Pen. Left of bag are H&K rail protectors. Extra pamphlets are data tables, SDO care guides and LaRue Tactical throw mount lever care information.]()

Trijicon SDO gear pouch with accessories. The gear bag is manufactured by Eagle Industries and is issued with every M27. Marine Corps T M 11758A-OR for the SDO/RMR and TM11810A-OR for the M27 are displayed top and bottom respectfully. M27 wrench is shown disassembled to left of SDO Lens Pen. Left of bag are H&K rail protectors. Extra pamphlets are data tables, SDO care guides and LaRue Tactical throw mount lever care information.

In 2010 Marine Corps Systems Command bought a pilot batch of M27s slated to replace or compliment M249 SAWs in four Infantry Battalions and one Light Armored Reconnaissance Battalion (LAR). All units will have an opportunity to train and deploy with the M27 throughout 2011 in the War on Terror. If the M27 operates well in combat, plans to buy additional M27s are in store. The current recommendation is to replace all the former SAWs with M27s throughout the rifle platoons but current individual assignments are at the discretion of the company commanders.

Function/ Nomenclature

Due to the M27s commonality with the M16/M4 rifles, user operation is similar. Instead of direct impingement, it is gas piston operated. It has a free floating barrel, and uses a more efficient bolt than a M16A4. These are the only major functional differences to the standard issue M16A4 that all Marines are familiar with. Cleaning the weapon is made much easier by the gas piston that keeps a good portion of the carbon out of the bolt carrier and upper receiver. Also, unlike the M16A4, the M27 is highly ambidextrous. Sling mounts, fire selector, and charging handle can all be made left or right handed with little modification. Point target range is 550 meters while area targets are 700 meters and maximum range is 3,938 yards. There are two barrel lengths; 19.5 inch and 14.5 inch with the 19.5 inch being the primary length used so far in the Fleet Marine Force (FMF).

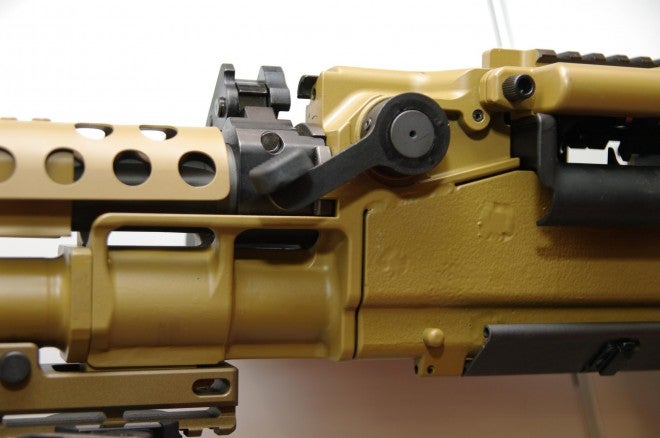

![The rail mounted BUISs are Knight’s Armament Corporation Flip Up Front Sight and the Micro Flip Up Rear Sight. Iron sights are peep hole types with a blade and protecting ears on the front sight. The rear sight is graduated from 200-600 meters with a Z setting for zeroing adjustments. Note USMC marked on front end. Also see the two pins on charging handle that can switch the lever to either side. Sling mounts are ambidextrous as is seen from this angle.]()

The rail mounted BUISs are Knight’s Armament Corporation Flip Up Front Sight and the Micro Flip Up Rear Sight. Iron sights are peep hole types with a blade and protecting ears on the front sight. The rear sight is graduated from 200-600 meters with a Z setting for zeroing adjustments. Note USMC marked on front end. Also see the two pins on charging handle that can switch the lever to either side. Sling mounts are ambidextrous as is seen from this angle.

The butt stock is similar to the M4 four position collapsable stock except that it is less sluggish and is six position. Unlike an M4 stock, it is easily removed by depressing the position toggle. It has one circular and two lengthwise sling keepers mounted at the rear allowing a diversity of slings to be used. The butt pad is rubber and can be removed with a hard twist counter clockwise. This reveals two battery compartments capable of storing AA, AAA, or Lithium 3 Volt batteries. Fully extended, the M27 is 37 inches (M16A4 length: 39.63 inches) and with the stock collapsed it is 33.66 inches (M4 collapsed length: 30 inches).

The M27 has a three position fire selector; “Safe”, “Fire”, and “Auto”, with the traditional H&K pictograms for each. Controls are on both sides of the receiver. The pistol grip is very comfortable and has a polymer pebbled surface to enhance grip. There is a battery compartment in the pistol grip that is held in place by a pivoting slider and the grip itself is more ergonomically designed than the standard M16A4 pistol grip. The magazine well has a flared opening that aids in magazine insertion but prevents Magpul PMAGs from being fully inserted. This leaves room for further magazine improvement if any manufacturer is up to the challenge. The weapon serial number is stamped upon both the upper and lower receivers right above the magazine release catch and left side safety in traditional European fashion. All M27 serial numbers begin in “USMC”. H&K proof marks are to the left of the serial number on the upper receiver.

The upper receiver has a 12 o‘clock rail that is interconnected with the Free Floating Rail System (FFRS) by a U-shaped lug. A captive locking screw adjacent to the magazine well additionally secures the FFRS. To take the FFRS off, grasp the bolt carrier with the thumb or index finger on the extractor in order to turn the strongest lug into a screwdriver. An important reason for a finger being on the extractor in such a position only the strongest lug is engaged and not the weak ones opposite the extractor. After only a quarter turn, the bolt carrier is unnecessary; hand strength is sufficient enough to complete disassembly. Only the 12 o’clock rail is marked with reference numbers up to 42 while the 3, 6, and 9 o’clock rails are left blank. Unfortunately, few attachments can be mounted directly underneath the handguard screw due to its proximity to the 6 o’clock rail.

![Buffer and buffer spring. The buffer tube has three vent ports at the rear and the buffer is marked HK on the tube face with a red dot in the center as well. The buffer spring is marked with red to distinguish it from a M16A4 or M4 buffer spring.]()

Buffer and buffer spring. The buffer tube has three vent ports at the rear and the buffer is marked HK on the tube face with a red dot in the center as well. The buffer spring is marked with red to distinguish it from a M16A4 or M4 buffer spring.

The M27 also comes with H&K rail protectors that take up most of the rail when mounted. They are secured at the end of the protector with a plastic indent. These too have a polymer pebble surface and provide good grip. There is no permanent sling mount but all M27s come issued with a rail mounted sling mount that uses a single screw to secure it in between rails. The ejection port cover is polymer. The charging handle has an extended release lever and pins so that it can switch to the other side. Right above the chamber on the left hand side of the barrel, it reads “HK 5.56mm” alongside an H&K proof mark. The bird cage flash hider can mount all attachments that an M16A4 can such as Blank Firing Adaptors (BFAs), muzzle caps and Bayonets (bayonet stud is included for the USMC OKC3S bayonet).

The bolt carrier and gas piston system are the true moneymakers of the M27. Their design is what makes the gun run so well and so reliable. The bolt carrier is similar enough to a M16A4 for it to lock into one and chamber a round. Whether or not the hybrid weapon will function reliably is unclear. On the flip side, a M16A4 bolt carrier cannot fit in an M27. The firing pin retaining pin is captive while the firing pin has a spring that keeps the bolt forward. The weapon will function regardless of the spring in the bolt or not. Operation will have minor degradation and there will be more frequent malfunctions but it will not interfere with function of the weapon.

![M27 gas system disassembled. Top left is the gas piston, this is the dirtiest part on the entire gun and is very simple to clean. Top right is gas piston rod which has a captive spring enclosed. The rod beyond the beveled half casing intrudes into the upper receiver and makes contact with the bolt carrier during operation. The Gas block is positioned just behind the bayonet stud and has a gas port facing downrange.]()

M27 gas system disassembled. Top left is the gas piston, this is the dirtiest part on the entire gun and is very simple to clean. Top right is gas piston rod which has a captive spring enclosed. The rod beyond the beveled half casing intrudes into the upper receiver and makes contact with the bolt carrier during operation. The Gas block is positioned just behind the bayonet stud and has a gas port facing downrange.

The gas piston system consists of the piston rod, piston and gas block. The piston rod has a captive spring and its lateral movement is no more than an inch at the most. The piston is the dirtiest part of the weapon after firing and is simple to clean. It fits into the gas block, which has a vent port facing downrange on top of the barrel. The gas port is only a few nanometers larger in diameter than the HK416 but this change in design cost the Marine Corps in excess of several hundred thousand dollars.

The M27 comes with three sighting systems; Back Up Iron Sights (BUIS), Squad Day Optic (SDO), and the Ruggedized Miniature Reflex (RMR). The Sight Unit, SU-258/PVQ Squad Day Optic was created for the M249 SAW with a contract from Trijicon in 2009 but has been since mounted on the M27. It is a 3.5×35 machine gun optic that is mounted to the rail via LaRue Tactical throw mount with duel locking lugs. It has Tactical Tough flip up dust covers and comes with an Anti Reflection Device (ARD, known as a honey comb for its pattern) screwed onto the objective lens. The reticle is an illuminated horse shoe around a center dot with a small post below. For distances of 100 and 200 meters the aiming markers are the top and bottom tips of the dot respectfully. For 300 meters it is the tip of the illuminated post and further ranges are marked on down the mil scale below the tip. The cross hair mil scale goes out to 35 mils on the horizontal lines and 40 mils on the vertical lines. On the vertical range scale there are range estimation stadia lines (Bullet Drop Compensator) that can provide accurate range estimation based on the shoulders of an average sized man (19 inches). It also has brackets for vehicle estimation both side and frontal views by using the tires.

![SDO and RMR mounted on top. Adjustment dials for elevation and windage are the two screw caps in front of RMR. Dust covers may positioned at any angle that the gunner is comfortable with. Also note tape over the Fiber Optic light collector to maintain a more crisp sight picture. Dust covers may be readily positioned at any angle to the SDO for ease of operation.]()

SDO and RMR mounted on top. Adjustment dials for elevation and windage are the two screw caps in front of RMR. Dust covers may positioned at any angle that the gunner is comfortable with. Also note tape over the Fiber Optic light collector to maintain a more crisp sight picture. Dust covers may be readily positioned at any angle to the SDO for ease of operation.

On top of the SDO is the RMR, a small reflex sight intended for engagements under 100 meters. Unlike the M240B MDO (Machine Gun Day Optic) RMR, which is rail mounted to the optic, the RMR is screwed in and cannot come off except with the use of tools. An important aspect of the RMR is that the dot is rather large in the holographic image and proper cheek wield cannot be maintained while acquiring a sight picture. A gunner must take careful measures to secure a proper zero and maintain it with good muscle memory. The RMR uses adjustment dials that require a flat blade and don’t have a dust cap. The SDO has turn knob adjustment dials with dust caps.

Performance

![SDO Reticle Mil scale as depicted in T M 11758A-OR. For range estimation of a human target, the average measurement of a height of 1.5 meters and a chest width of 19 inches is used. For a man sized target at 100 meters, the shoulders will touch the two mil dots opposite the center red dot. For 200 meters, shoulders will touch the lateral sides of the illuminated horse shoe and for 300 meters, shoulders will touch the two disconnected end at 6 o’clock. For 400 and 500 meters shoulders will align with the lateral line at 4 and unmarked 5. From 600-1000 meters the shoulders will fit between the respective mil dots and lateral mil scales. For vehicle estimation the tires will fit between the mil dot and the end of the solid lateral mil line in the front/rear view and from edge of mil line to mil line in the side view.]()

SDO Reticle Mil scale as depicted in T M 11758A-OR. For range estimation of a human target, the average measurement of a height of 1.5 meters and a chest width of 19 inches is used. For a man sized target at 100 meters, the shoulders will touch the two mil dots opposite the center red dot. For 200 meters, shoulders will touch the lateral sides of the illuminated horse shoe and for 300 meters, shoulders will touch the two disconnected end at 6 o’clock. For 400 and 500 meters shoulders will align with the lateral line at 4 and unmarked 5. From 600-1000 meters the shoulders will fit between the respective mil dots and lateral mil scales. For vehicle estimation the tires will fit between the mil dot and the end of the solid lateral mil line in the front/rear view and from edge of mil line to mil line in the side view.

On live fire ranges the M27 has preformed flawlessly with sub Minute of Angle groups typical. Transitioning from Semi to Auto is simple and very effective when switching from long range targets to quick bursts on close engagements. On a recent live fire training evolution, the unit’s M27s went through more than 300 rounds per gun in the span of an average of 20 minutes in completing an evolution. The author only experienced one jam, caused by a double feed while simultaneously gripping the magazine well and magazine.

![Close up display of magazine followers. From left; PMAG, H&K steel, original follower, tan anti-tilt follower. Issued STANAG magazines and those without the tan anti-tilt follower often have difficulty being inserted. The anti-tilt magazines were also introduced with the M27 in mind because the rate of fire was too much to keep up to with the previously standard issue magazines. Interestingly enough, H&K steel 30 round magazines have no issues whatsoever and in fact, are drop free unlike the others.]()

- Close up display of magazine followers. From left; PMAG, H&K steel, original follower, tan anti-tilt follower. Issued STANAG magazines and those without the tan anti-tilt follower often have difficulty being inserted. The anti-tilt magazines were also introduced with the M27 in mind because the rate of fire was too much to keep up to with the previously standard issue magazines. Interestingly enough, H&K steel 30 round magazines have no issues whatsoever and in fact, are drop free unlike the others.

The gun is extremely controllable on fully automatic provided a proper stance and proper technique are used. M27 gunners were engaging targets well out to 500, 600 meters with one shot hits and immediately taking out near targets of opportunity with bursts and magazine dumps. For Military Operations in Urban Terrain (MOUT), the M27 performed at the same level as an M4, if only a little longer and heavier (7.9 lbs unloaded). The RMR holographic sight was perfect for live fire kill house evolutions where Marines couldn’t afford to be tunneled into the SDO while in a MOUT environment.

![Bolt carrier group and charging handle disassembled. This is relatively the same condition of parts after extended firing. Charging handle will function in M16A4.]()

Bolt carrier group and charging handle disassembled. This is relatively the same condition of parts after extended firing. Charging handle will function in M16A4.

But the M27 is not without drawbacks. Since the magazine capacity can barely match the rate of fire, gunners would routinely empty entire magazines in seconds only to reload and repeat. Marines were running through evolutions with an excess of sixteen magazines in pockets, pouches and whatever else was improvised. Many more magazines were split up among the squad to carry extra. In comparison, standard load for a rifleman is seven magazines and M27 gunners were carrying nearly three times that amount (21 non tilt follower magazines). Magazine couplers helped with reloads but they take up space on flak jackets and in pouches. PMAGs will not work because of the frontal plastic bevel, which prevents full insertion into the magazine well. The bevel can be filed down to work but, this is highly questionable and against regulation. Questions have been raised on the use of drums designed for the M16A4. These work reliably but have not been tested in military operations overseas. They also cannot stand up to extreme temperatures that military equipment operates in. Surefire has just come out with 60 and 100 round magazines that work reliably in the M16A4, but not in the M27. Currently, Surefire is working to redesign the new magazines in order to work in the M27 as of March 2011.

![Top view of bolt carrier with captive spring fully extended. The large lever on top of the carrier serves two purposes: to keep the firing pin secure during disassembly and it acts as an internal safety. It prevents full travel of the firing pin unless it is struck by the hammer which pushes it up and the firing pin forward.]()

Top view of bolt carrier with captive spring fully extended. The large lever on top of the carrier serves two purposes: to keep the firing pin secure during disassembly and it acts as an internal safety. It prevents full travel of the firing pin unless it is struck by the hammer which pushes it up and the firing pin forward.

Grippods were an issue as well. Some gunners had theirs broken within the opening minutes of evolutions. These fore-grip combinations are not designed to be used with machine guns, which need a rugged platform to anchor themselves to the deck. The Grippod does not provide enough elevation for a gunner to successfully engage targets at an incline. Also, it is worth noting that occasionally the screws on the LaRue throw lever mounts would come loose after an extended period of sustained firing. Inside the mount there are five screw holes for connecting the optic but only two screws in place.

The M27 barrel is not meant to be readily replaced if there is a hot barrel. Tests have shown that the sustained rate of fire is 36 rounds per minute (rpm) at 120 ℉ for a 600 round load. The cyclic rate of fire is 700-900 rpm (M249 SAW 850 rpm). Little guidance has been provided in the event of a hot barrel except for the shooter to be careful and conserve rounds. During the early testing of the M27 there was a torture test of the guns reliability that was called the “Wells Test” named after the Captain who implemented it. It took 1 minute and 36 seconds to fire through 22 fully loaded magazines all lined up next each other without a single malfunction. Standard issue red M16A4 BFAs mount to the flash hider but 5.56x45mm blanks prevent full operation of the M27. On Semi, rounds cannot fully cycle the M27 and it must be charged every round. On Auto, the gun goes through an average of two rounds before it must be charged again. Currently, yellow M4 BFAs are now standard and their performance is expected to be substantially better.

Small parts begin coming off after extended use of the weapon both in evolutions and everyday use. Battery compartment covers, optic dust covers and ARDs have all been seen to come apart and off if not constantly checked. Most units have it as Standard Operating Procedure to secure serialized gear to the weapons with zip ties and 550 cord. Gunners must be wary of placement with such extremities because if positioned in certain areas they melt if in contact with the barrel (PEQ16) or interfere with disassembly of the weapon (SDO to FFRS).

![M27 disassembled into major components. Note silver ball bearings on the buffer tube. Also, on the barrel below the silver captive spring cap of the gas piston rod is the melted remains of a ziptie previously used for securing the PEQ16.]()

M27 disassembled into major components. Note silver ball bearings on the buffer tube. Also, on the barrel below the silver captive spring cap of the gas piston rod is the melted remains of a ziptie previously used for securing the PEQ16.

Conclusion

The most pressing changes that need to be addressed on the M27 are the bipod and magazine predicaments. Issuing efficient, rugged bipods and higher capacity magazines are what the M27 needs in order to be more effective to the infantry squad’s mission; other problems pale in comparison. Apart from these issues, the Heckler & Koch M27 has made a significant impact on the way Marine squads conduct operations. However, the jury is still out on the M27 and many are waiting on results of the gun in country. The M16A4 familiarity makes it perfect to issue to Marines already so ingrained with that weapon. Its reliability and weight take away the M249 SAWs principal drawbacks. Some have even speculated that this weapon is an indirect path that the Marine Corps is taking to get more reliable squad level small arms into the hands of Marines without going through the headache of replacing the M16A4. Such programs and rifles have faced opposition ever since their inception (SPIW 1960, ACR 1986, OICW 1990, XM8 2002, SCAR 2007). Overall this is a very fine weapon and has definitely exceeded expectations. The grunts love it, and that is the most enduring compliment any firearm or piece of gear could earn.

![FFRS captive locking screw extended out. Sling mount is on left side and can be moved anywhere on the rails. Note the close proximity of screw block to rails, preventing some attachments to the rail.]()

FFRS captive locking screw extended out. Sling mount is on left side and can be moved anywhere on the rails. Note the close proximity of screw block to rails, preventing some attachments to the rail.

Article by Miles Vining. Special thanks to David Dimaruo, Tom Durwood, Liza Ponomarenko, Edward Young and the Marines and Corpsmen of 3rd Platoon, Charlie Company, 1st Battalion, 9th Marines.